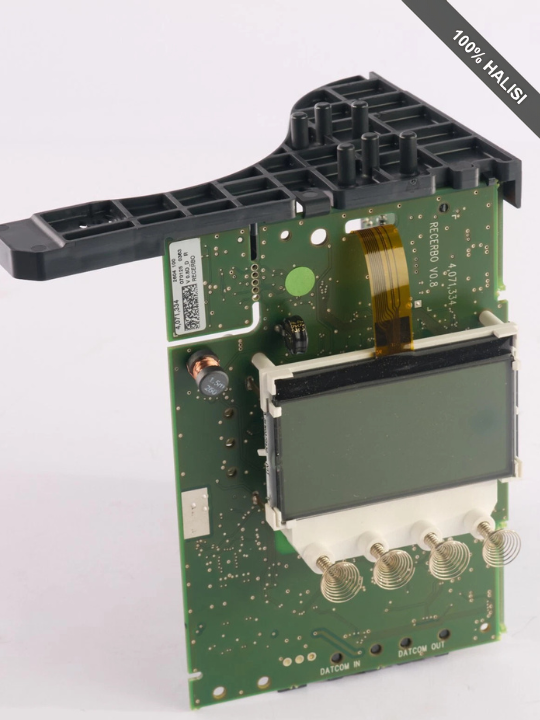

The Fronius Print Recerbo Board/Card (Part number 4,071,334,Z) is a replacement printed-circuit board (PCB) designed to maintain or restore functionality in compatible Fronius inverters (e.g., Symo, Galvo series). This genuine OEM component ensures system integrity and avoids compatibility issues that can arise with generic aftermarket parts. For the Tanzanian market, where solar installations are increasingly common and service resources may be limited, this board supports long-term reliability and avoids costly inverter downtime.

Features & Benefits

- OEM quality, branded Fronius: Using the genuine Print Recerbo board ensures full compatibility, proper fit-and-function, and adherence to original manufacturer standards—minimizing risk of unexpected failures.

- Restore inverter performance: When control electronics degrade or fail, replacing with this board can bring the inverter back to full operational status, avoiding full inverter replacement.

- Supports serviceability: For Tanzanian solar system owners and installers, having access to a dedicated spare part means quicker repairs, less downtime and improved system reliability.

- Cost-effective maintenance: Rather than replacing the entire inverter (which could be high cost and downtime), swapping in the board can be a lower cost maintenance option.

- Spares availability advantage: Given the remote or challenging logistics in some Tanzanian areas, offering a known part number for servicing simplifies inventory, ordering and servicing.

- Quality assurance: Using the genuine Fronius board helps maintain warranty support (where applicable) and ensures systems remain aligned with brand standards, which is a plus when selling to commercial clients.

Use Cases

- A medium commercial rooftop solar PV pilot in Dar es Salaam using a Fronius Symo inverter: The original control board fails due to voltage transients—installer replaces the Print Recerbo board, restoring operation without full inverter swap.

- A remote off-grid solar installation (guest lodge) in Tanzania where servicing trips are costly: Having this replacement board locally stocked ensures the inverter can be repaired quickly, reducing production loss.

- Solar service companies offering preventive maintenance: They carry the Print Recerbo board to address control-board failures proactively in older Fronius inverters across Tanzanian sites.

- Systems looking to extend lifetime: Owners of 5-10 year old Fronius inverters choose to replace this board to maintain performance, instead of budgeting for full system replacement.

Value Propositions

- Minimises risk of downtime: For commercial system owners, downtime means lost production or revenue; this part helps mitigate that risk.

- Cost-saving maintenance path: Replacing a board is significantly less than replacing the whole inverter; good value in Tanzanian cost-sensitive market.

- Professional service offering: Solar installers in Tanzania can market “OEM spare board available” as a sign of professional grade service and longer system life—differentiator versus low-cost installs.

- Supports local logistics: Having a known part number means better planning, order tracking, and less downtime waiting for unknown generic components.

- Long-term reliability: Using original parts reduces risk of mismatch, failure due to incompatible components, thereby improving overall system reliability in hot/dusty Tanzanian environment.

Local Market Positioning (Tanzania)

- In Tanzania’s growing solar market—residential, commercial and industrial—the availability of genuine Fronius spare parts like the Print Recerbo board supports robust service networks and confidence among system owners.

- Installers can position this part as part of a “service-ready package” for Fronius inverters: “We carry spare control boards so your system downtime is minimised.”

- For business clients (schools, hotels, small factories) who rely on solar for cost control and uptime, emphasise that system maintenance is localised and parts are accessible, reducing risk and total cost of ownership.

- In a market where many installations may be using lower-cost inverters with limited aftermarket support, advertising genuine spare-part availability for Fronius gives a strong competitive edge: “premium brand, long support”.

- Because environmental conditions in Tanzania (heat, dust, variable grid, frequent storms) are harsh, system reliability matters; a working replacement board helps maintain the brand’s reliability promise.

Technical Specification

| Part Number |

4,071,334,Z |

| Category |

Symo Accessories / Inverter Spare Parts |

| Manufacturer |

Fronius International GmbH (Austria) |

| Product Type |

Replacement Printed Circuit Board (PCB) |

| Function |

Restores or replaces the inverter’s internal control board for continued operation |

| Compatibility |

Fronius Symo, Fronius Galvo, and selected SnapINverter models |

| Installation Type |

Internal component replacement (performed by qualified technician) |

| Electrical Rating |

Low-voltage DC signal control board (operates within inverter DC bus system) |

| Connector Type |

Multi-pin terminal interface with ribbon and modular connectors |

| Mounting Type |

Plug-in board, internal bracket mounting |

| Protection Type |

Conformal-coated for moisture and dust resistance |

| Firmware Support |

Preloaded with Fronius standard firmware (can be updated via inverter software) |

| Material |

FR4 high-strength fiberglass PCB with copper trace layers |

| Operating Temperature Range |

−25 °C to +60 °C |

| Dimensions (H × W × D) |

Approx. 120 mm × 80 mm × 20 mm |

| Weight |

Approx. 0.2 kg |

| Maintenance |

Replaceable module; requires anti-static handling procedures |

| Safety & Compliance |

Conforms to IEC 62109-1 and IEC 62109-2 (safety of power converters) |

| Application |

Replacement and repair of Fronius inverter control systems |

| Included Components |

PCB module, installation guide, anti-static packaging |

| Country of Origin |

Austria |